The Boyd Difference for Advanced Display and Touchscreen Solutions

We’ve innovated our advanced display material fabrication processes over the last 20 years to consistently deliver high quality optical display components with exceptional tolerance control at high volume mass production to help the most sophisticated mobile electronics brands in the world optimize display performance and component cost. We continue to tirelessly push advanced display component process innovation to help our customers continue to differentiate and leverage our display heritage to help brands new to advanced displays navigate this complex technology.

Boyd’s Advanced Display Heritage

- 15+ years of field-proven performance in display applications

- 1 billion + display components shipped

- 5 million + Micro OLED component installations

- Trusted advisor to display OEMs and Tier 1 partners

- 电子和电动汽车应用的关键展示解决方案的先驱

- 端到端内部验证

Segmented Frame Technology

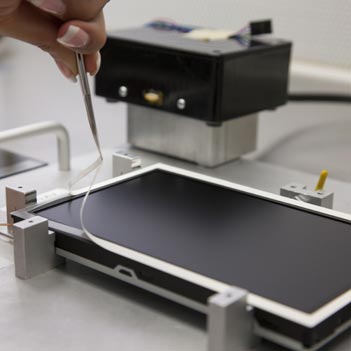

Boyd’s proprietary Segmented Frame Technology leverages our deep, innovative processing knowledge with proprietary designed advanced rotary converting equipment to integrate multiple material layers at maximum raw material utilization. We’re able to combine multiple display bill of material (BOM) components in one-pass manufacturing for one easy-to-assemble final product deliverable that helps our customers accelerate assembly processes as they integrate display modules into their applications.

- 耐受性控制降至+/- 0.05mm

- Integrate multiple materials and display components into one easy-to-assemble final product

- 改善装配周期

- Maximize raw material use

- 最小化材料损失

- Integrate display mount adhesives, bezel bonds, cushions, spacers, insulation, thermal management, shielding performance, and optical functionality into one component

材料科学和处理专业知识

Optical materials are designed to enhance display performance and efficiency. To do this effectively, they must be visually perfect and free of foreign debris and contaminants. These specialty materials require special protocols to assure zero defects impacting how optical and display materials are transported, packaged, stored, handled, and processed.

博伊德(Boyd)在所有主要地理位置中都保持各种清洁室环境,并使用过程和协议,以处理和制造显示材料的清洁度要求越来越高:- 无污染的材料存储和处理协议

- 洁净室的原材料裂缝和准备过程

- 洁净室高级旋转转换制造线

- Cleanroom flat bed converting manufacturing lines

- 洁净室的化妆品检查

- Class 100 clean rooms

- Class 1000 (Class 1K) clean rooms

- 班级10000(10k级)干净的房间

- Class 100000 (Class 100K) clean rooms

- UV sensitive clean room manufacturing

- 温度敏感的材料处理过程

Cleanroom environments include ongoing monitoring to assure optical materials and display components are contaminant-free and on-specification:

- 过滤器安装泄漏测试

- 空气粒子计数测试

- Airflow velocity testing

- 温度测试

- Relative humidity testing

- Light intensity level testing

- Sound pressure level testing

- Room pressurization testing

供应链

显示模块值链对许多玩家非常复杂。博伊德(Boyd)帮助您简化这一点,以最佳的总成本提供差异化的性能。

原材料供应商创新材料配方并增强材料性能。它们生产大格式卷和原始展示材料的床单。博伊德(Boyd)具有战略性的供应关系,约会50多年,领先的展示原材料供应商(例如3M,TESA和NITTO)。我们继续积极寻找具有创新材料的新进入者,可以帮助我们的客户区分显示体验。

Many OEMs rely on Display Integrators to design and deliver custom display modules that meet their needs. Display Integrators are experts in display module design and assembly, delivering on-specification display subassemblies to OEMs for integration into their final product. Boyd has 15+ year relationships with the world’s leading display integrators. We continue to establish new strategic relationships with new market entrants as our customers evolve their preferred display integrator partners.

关键显示术语要知道

|

Term |

定义 |

|---|---|

|

电池粘合剂 |

磁带将电池固定在显示屏堆栈附近,并具有高温抗粘合剂。提高产品安全性并延长电池寿命。 |

|

监管标签 |

UL compliant regulatory labels assure high brand compliance, safety warnings, and traceability。 |

|

相机垫圈 |

粘合剂和胶卷or foamthat保护scamera modules from water, vibration, and contaminants。延长终生并改善performance。 |

|

Capacitive Touch Module |

Tactileinterface surface that启用users to interact with a设备通过touch.Hasbeen replacingtraditional membrane switches, elastomers, and full travel keyboards as the primary input method on many产品设计。 |

|

导电背光外壳 |

机械和热导导的结构同时支持背光单元,并将热量从显示屏转移到环境环境。可控的背光工作温度最大化颜色活力和显示生命周期。 |

|

Diffuser Film |

Specialized film that evenly distributes light across the screen. Optimizes full display visibility for better screen clarity, vivacity, and color trueness at a wider viewing angle. |

|

Display Integration |

Minimize engineering, design, and supply chain complexity with fully integrated display subassemblies that include all display components, optical films, adhesives, and gaskets with a display housing and all connectors for streamlined display assembly into your devices. |

|

Brightness Enhancement Film |

Specialized film thatintensif即显示亮度,improvesthe用户体验and展示energy efficiency. |

|

EMI Shielding |

Shielding layer to reduce electronic malfunction susceptibility by blocking unwanted external electromagnetic waves to improve device and signal reliability. Eliminates internal display component cross talk. |

|

泡沫Adhesives |

防止对设备的强烈显示粘附的破裂或分离的屏幕,可缓冲以吸收冲击和振动。 |

|

Front Frame Gaskets and Seals |

Adhesive (foam) gaskets that ruggedize the joint between displays and front glass panels. Cushions vibration and shock to extend display life and improve customer satisfaction. |

|

(Graphite) Heat Spreaders |

薄质,轻巧的热传导材料,可从高性能组件中散发出热量远离局部热点。保持安全的触摸温度并防止过热。 |

|

LCD |

Liquid Crystal Display |

|

Lightguide面板 |

面板或电影that concentrates and amplifies light from the backlight to the viewer. Improves display richness, sharpness, and efficiency. |

|

LED |

Light Emitting Diode |

|

OLED |

有机光发射二极管 |

|

Optically Clear Adhesives (OCAs) |

Optically clear adhesive that mechanically joins surfaces with a matching refractive index to reduce light loss between substrates and give the appearance of being optically clear or invisible. Maximizes display clarity. |

|

Protective Film |

电影intended to prevent screen scratches or cracking during manufacturing, logistics, assembly, temporary consumer use, or durable long term protection. |

|

反射胶片 |

通过显示屏反射光的膜,将所有生成的显示模块光集中到观看者。到达用户的更多光线最大化能源效率,表现生存和颜色真实。 |

|

Segmented Frame Display Bonding Gasket |

Boyd-developed proprietary high volume manufacturing processes to cut four pieces of a display frame separately and assemble into one deliverable with zero gap joint tolerances for waterproofing and dimensional control. Passes IP67 and push-out testing. Enhanced sealing performance with best raw material utilization. |

|

Speaker Mesh |

声学上透明的合成或编织金属网格过滤器可在密封水和污染物的同时提供高质量的音频。将水和颗粒物密封来自具有声音透明过滤器的设备,用于高质量的扬声器和麦克风。 |

Closing

Boyd has shipped more than 1 billion display components over 15+ years. We’ve helped the leading mobile electronics brands differentiate their products with high performance displays that enrich the immersive consumer experience, reduce weight and battery drain while pushing the boundaries in creative manufacturing that optimizes cost.

Have questions? We're ready to help!